How to Check for Water in Diesel?

It’s crucial to monitor the diesel in your tanks if you don’t want to incur expensive diesel repairs caused by water in the system. In order to prevent water from accumulating in your diesel, your mechanic will conduct their own testing, but there are a few things you can do yourself:

Check the Water Separator

The fuel system of most diesel automobiles includes a water separator. During routine diesel maintenance checks, your mechanic will examine and empty the separator, but you can keep an eye on it to ensure it isn’t accumulating a lot of water.

Examine the Diesel Storage Tanks

Opening your tanks and looking inside is one of the simplest ways to check for water. An expert mechanic detects germs and water contamination just by looking and smelling at the gasoline.

Test the Fuel

Water-contaminated diesel is visibly darker than clean diesel fuel, which is light-coloured and clear. So, if the diesel is visibly hazy or dark, there may be water in the system.

Chemicals for Testing Water

A water testing tool that detects the presence of water quickly can be used to check diesel fuel. When these items come into touch with water, their colours change, making it easy for technicians to identify diesel that has been tainted.

Diesel Fuel Contamination Test

Many labs perform several tests to check the different types of diesel contamination. These labs will take fuel samples, perform different tests, and give feedback on the quality of the diesel.

To check the water contamination of the diesel, ASTM D2709 sediment/water lab test is performed.

Sediment/Water Lab Test

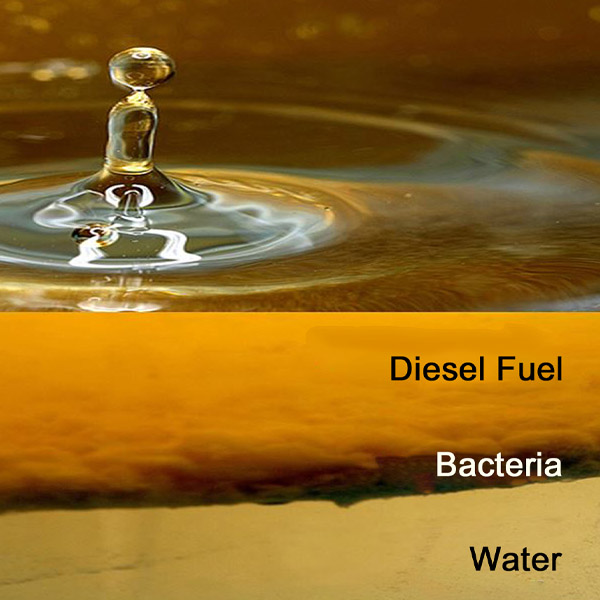

Water contamination should be monitored and reduced as it is the main cause of microbiological fuel contamination.

Water can condense on the fuel over time and collect at the bottom of the tank, providing ideal circumstances for microbial development that might result in sediment formation. Testing for water and sediment will determine how much of each is suspended in the fuel.

How to Prevent Diesel Contamination?

Diesel water contamination can be prevented by using different types of dispersants. Usually, there are two types of dispersants: emulsifiers and demulsifiers. An emulsifier works to combine water and fuel, while a demulsifier separates water from other liquid bodies.

If you want to stop water from harming your diesel engine and affecting the quality of your fuel, you must use a demulsifier. In the event that you choose an emulsifier, the high pressures at the injector tips will transform the water into steam and may cause

the injector tip to explode, costing you a lot of money to replace. Emulsifiers can be quite useful in petrol applications, whereas demulsifiers are more effective in diesel engines.

A practical and preventative measure to keep the water separated for simple removal is to add a demulsifier to your fuel before problems arise.

Diesel Treatment for Water

The more water in your engine, the more potential issues there are. Check the diesel for water before you start the removal procedure. You can use a bilge pump to remove it if only a tiny amount is present manually.

If your fuel tank has a larger volume of water, allow your machine or vehicle to wait and let the water in the tank settle. A demulsifier can help with the separating process in this case. A long pump that extends to the bottom of the tank can then be used to remove the water.

Frequently Asked Questions (FAQs)

What leads to water condensation in tanks holding diesel fuel?

As diesel fuel doesn’t have the same vapour pressure as petrol, it can induce water condensation in fuel tanks. Water condenses on the cooler tank walls when the tank cools at night, drawing moist air back into the tank.

Water can also make its way through an open fill port or a damaged tank, leading to water condensation.

How can I keep fuel from being contaminated by microbes?

Regularly check for signs of diesel pollution to ensure your fuel is in the best possible condition. It’s critical to have your diesel inspected by a professional every year to ensure there are no indications of impending issues if you want to avoid using contaminated diesel.

What will happen if water gets into diesel fuel?

Diesel and water don’t mix; they remain separated. Therefore, water in your tank sinks to the bottom if there is any. Your tank will rust, and algae will bloom due to that water, clogging and damaging your fuel filters.

Can Water-Contaminated Diesel Affect Your Engine?

Contaminated diesel has adverse effects on your vehicle’s engine. It can corrode engine parts, promote acid buildup, impair lubrication, and even damage injectors explosively.

Last Words

You need to take quick action as soon as you detect a sign of diesel water contamination to prevent serious problems. I hope this article provided you with handy tips on preventing diesel contamination and keeping your vehicle and machinery safe.